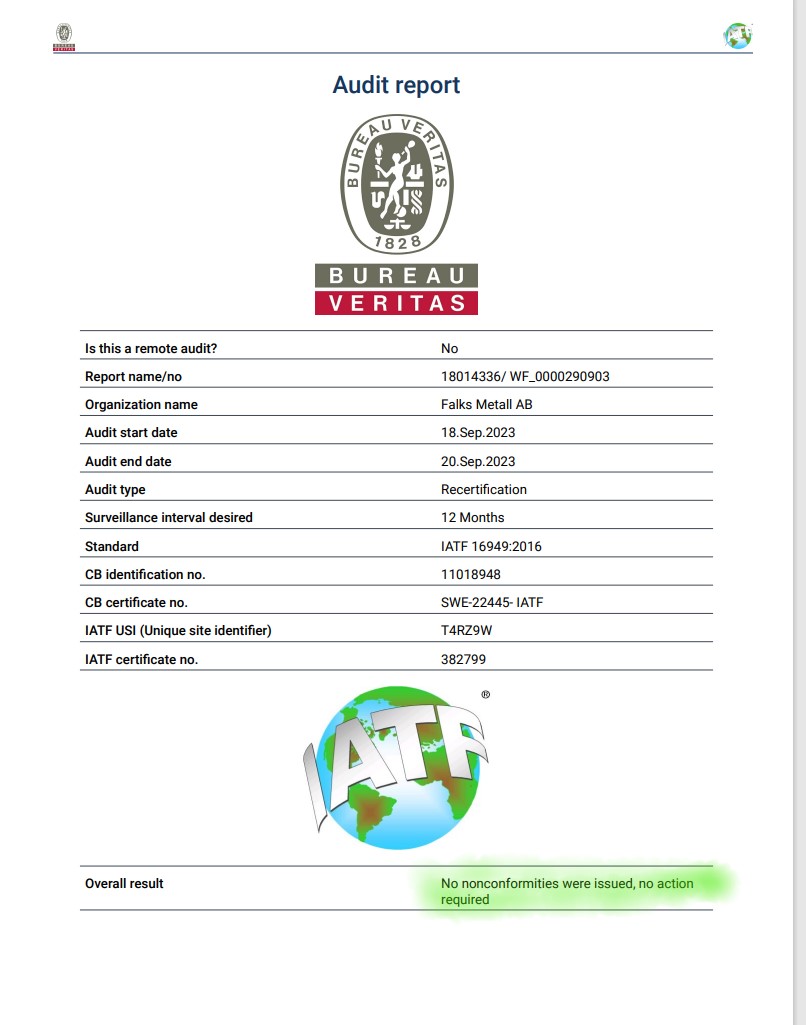

NO NONCOMFORMITIES – IATF 16949 AUDIT

We are happy to announce that we had no noncomformities in the IATF 16949 audit for year 2023. Same result as for the audit for

SCREENING AND INVENTORY OF SCOPE 3 EMISSIONS

Last year, Falks Metall let a group of IIIEE students at Lund University investigate, among other things, scope III emissions for the most commonly used

TOWARDS 2023

We are getting closer to the end of year 2022. A year characterized by uncertainty because of war, ongoing pandemic, increasing raw material prices and

NEW MILLION ORDER

We can announce today that we have received a new order for hot pressed brass components! Hot pressing is a cost-effective method that provides high

NEW PROJECTS

Hope you had a nice Easter holiday! Here at Falks, we have rested before this week’s exciting challenges. We have 82 new turned articles on our

RESEARCH PROJECT DASH BOARDS

Falks Metall’s work with dash boards began in connection with the national project Produktionslyftet. The paintings became a daily gathering point for most employees. In

WE ARE PROCESSING ECOBRASS®

Lead is a common alloying element in brass, but due to its health hazard, it is becoming increasingly important to look at lead-free alternatives. Falks

ALUMINIUMBRONS CW307G

Ett av alla ställ den här veckan är en artikel som bearbetas i CW307G, en kopparlegering som benämns aluminiumbrons. CW307G är en stark och korrosionsbeständig

ALUMINUM BRONS CW307G

One of all the stands this week is an article processed in CW307G, a copper alloy called aluminum bronze. The CW307G is a strong and

We are happy to announce that we had no noncomformities in the IATF 16949 audit for year 2023. Same result as for the audit for the quality system ISO 9001. From the audit report, we are pleased to read: Core values have been able to maintain and opportunities for satisfactory business and a living management […]

Last year, Falks Metall let a group of IIIEE students at Lund University investigate, among other things, scope III emissions for the most commonly used steel they purchase. The result was used in a calculation sheet that could be used in discussions with customers on climate footprint of their orders. This year, Falks Metall wanted […]