3 keys to an innovative facility

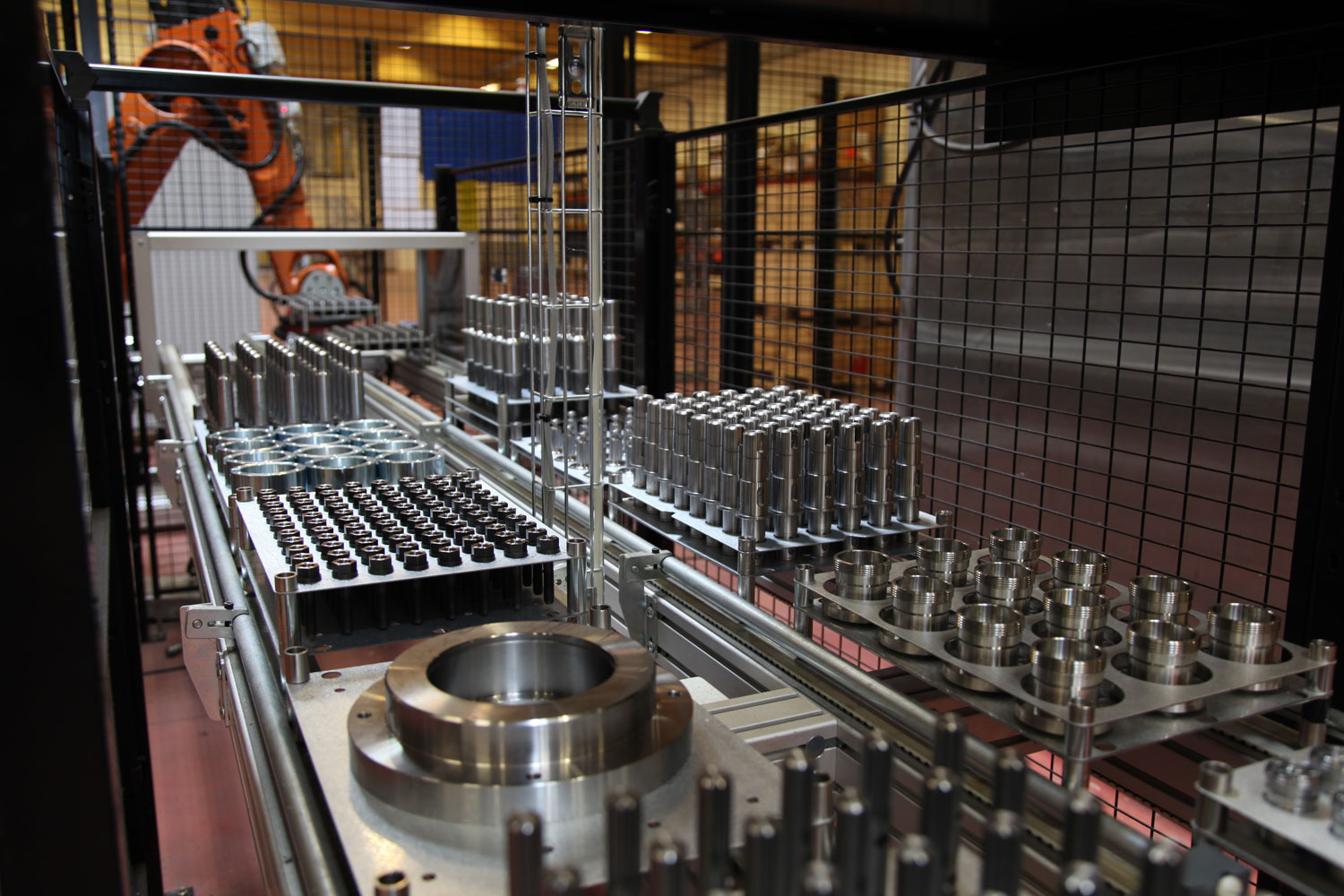

1. The carrier

It starts with what we call "The Bearer". A pallet with RFID marking that carries substances. The pallet can be sent to exactly the parts of the facility required for the specific detail. We have 100% traceability throughout the production phase.

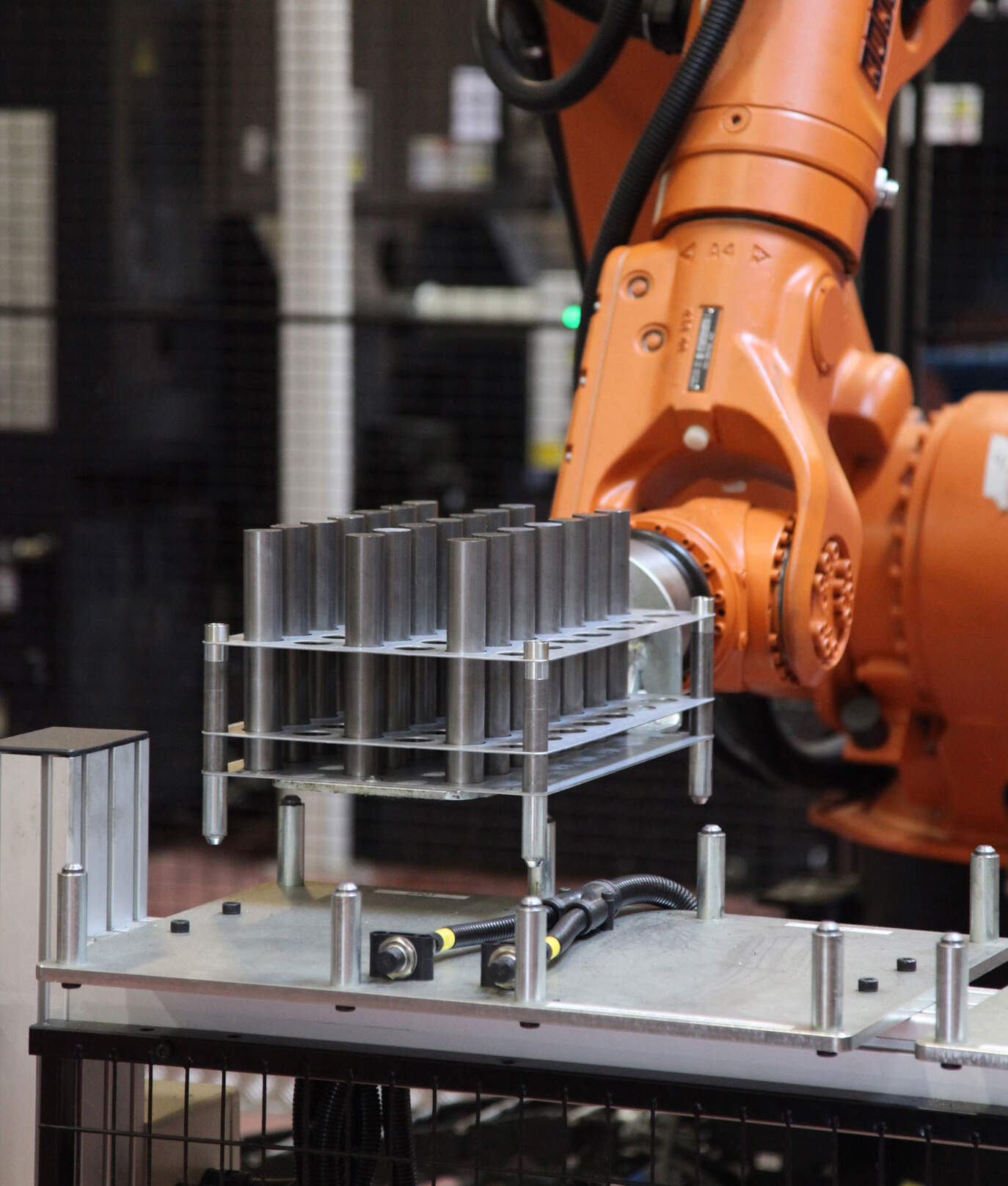

2.The subject

As long as the subject can stand on a pallet, we can do anything with it. The principle "near-net-shape" gives great gains in processing, weight, material waste and processing opportunities.

3. Integrated production cells

The substance is on the pallet that is RFID-labeled. Now it can be sent around the production plant completely automatically. Turning, grinding, hardening, washing, marking or whatever you need. Completely visible at all times via our vision system for control and monitoring.