Turning and milling

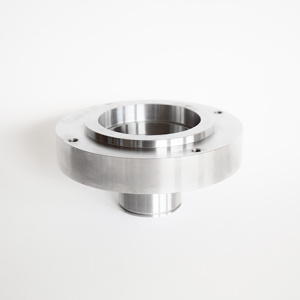

Falks Metall manufactures turned and milled parts with small tolerances in small and large volumes. Our 7,500 square meter facility has CNC lathes, transfer machines and longitudinal lathes. This is supplemented with an FMS plant where we process plaster, cast and forged blanks into finished details.

A large part of the development in and the challenge with our work is in its core – the material. We manufacture details in most common materials; steel, aluminum, stainless steel, brass as well as titanium, Nimonic and other special alloys. At the same time, we are constantly looking for new materials with completely new properties that can break new ground.

Our business is governed by a process mindset where we use SPS systems, standardized working methods and our employees’ high will and competence to manage our business. We use RFID marking for 100% traceability through production. The assignments vary in scope, in dimensions and degree of complexity. See below for examples of articles.

Dimension Ø30-Ø230

Dimension Ø5-Ø30

Dimension Ø2-Ø5

Milling articles

Ask us what you want

We respond within 24 hours. Ask us about:

- Standard material

- Special alloys

- Turning

- Milling

- Zero errors - how do we get there?

- Our company in China