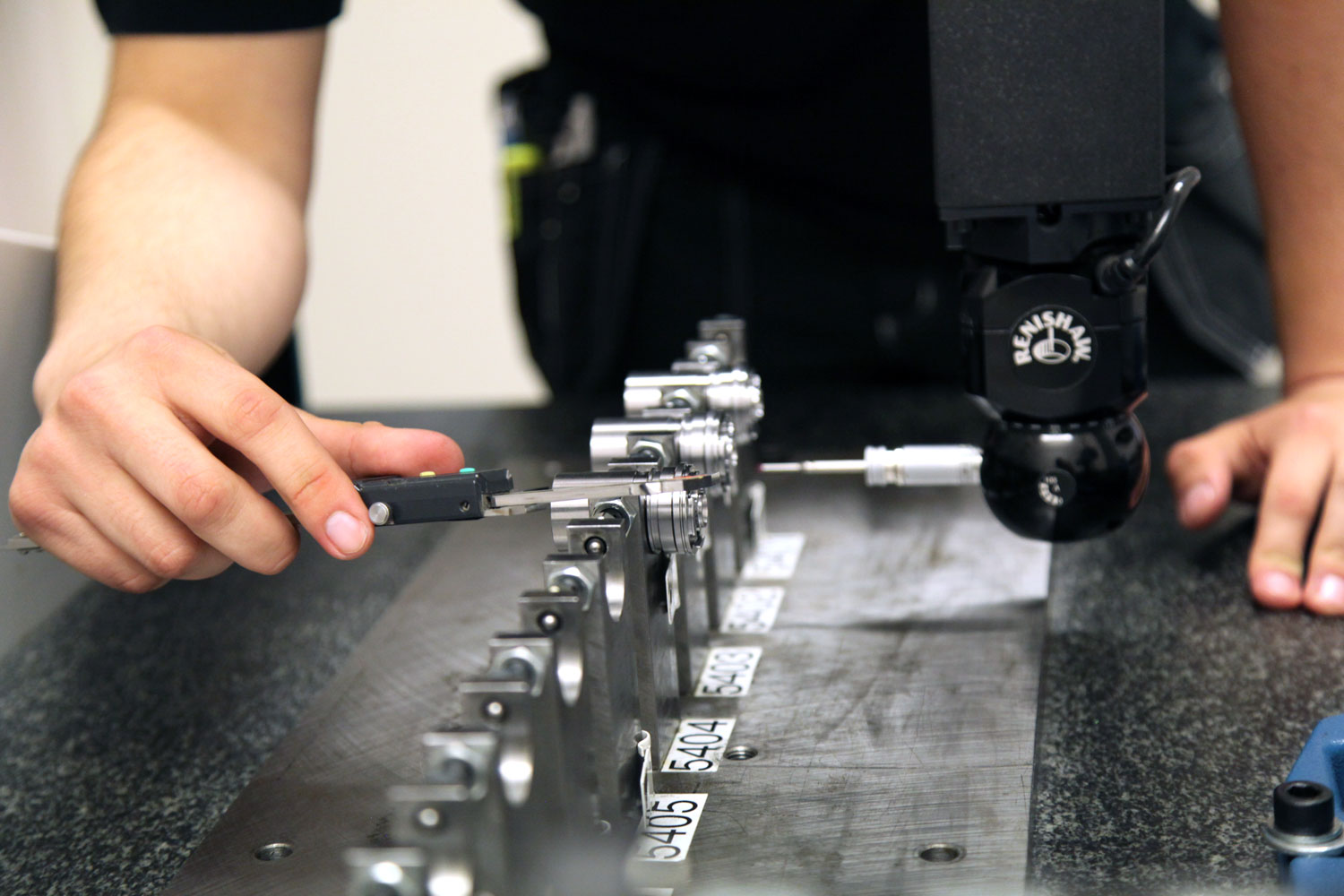

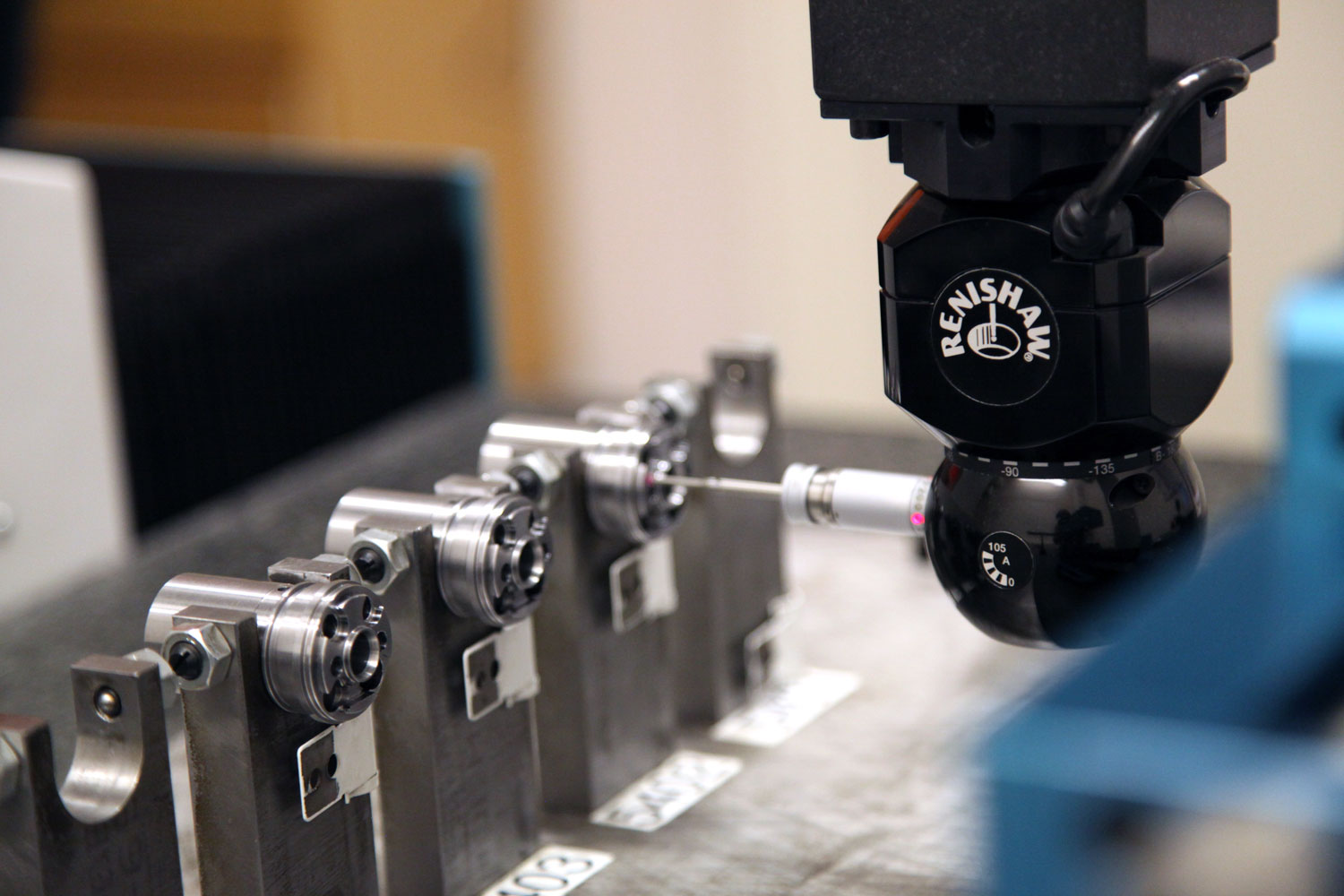

Kontroll och mätning

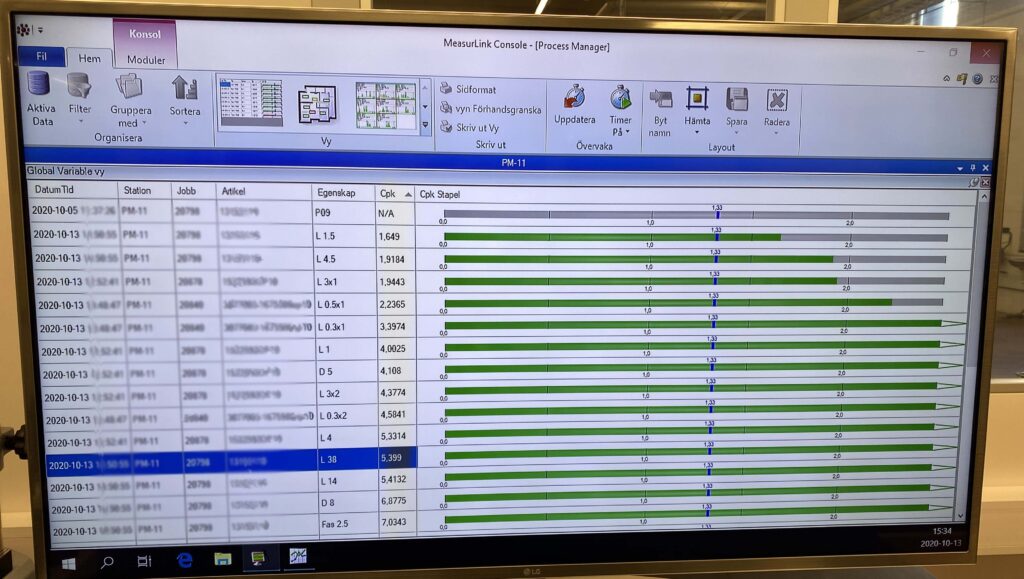

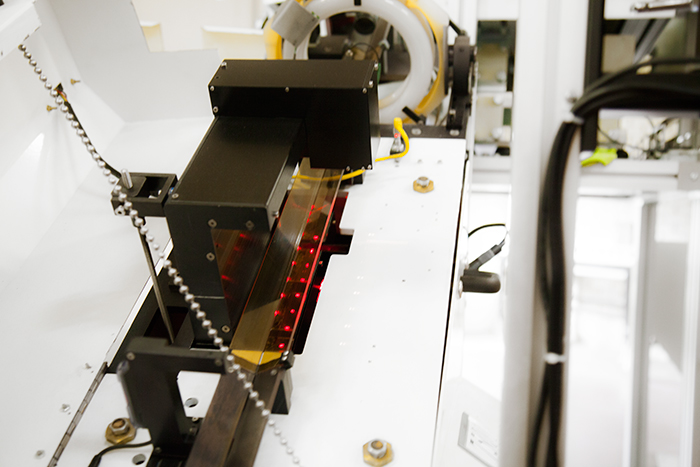

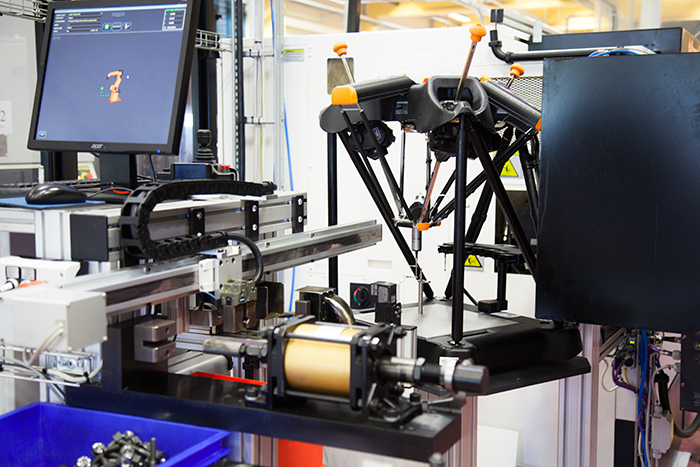

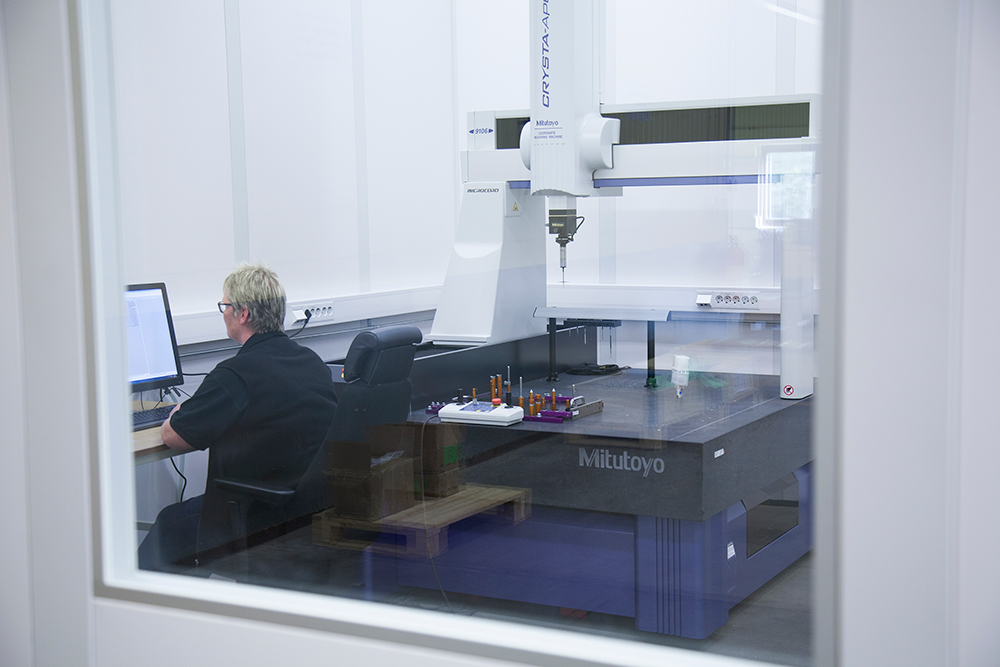

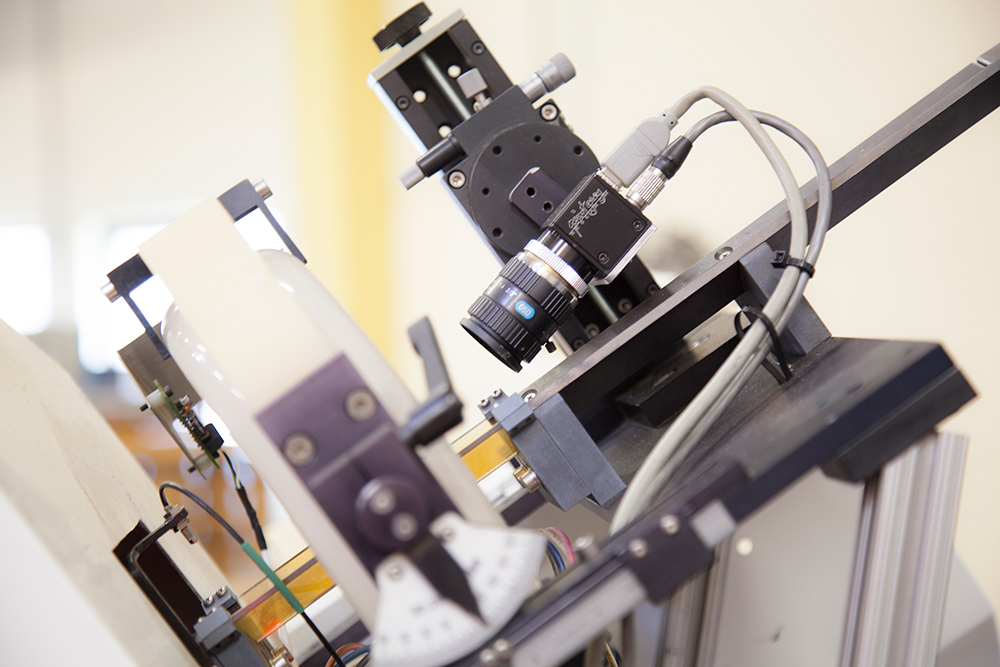

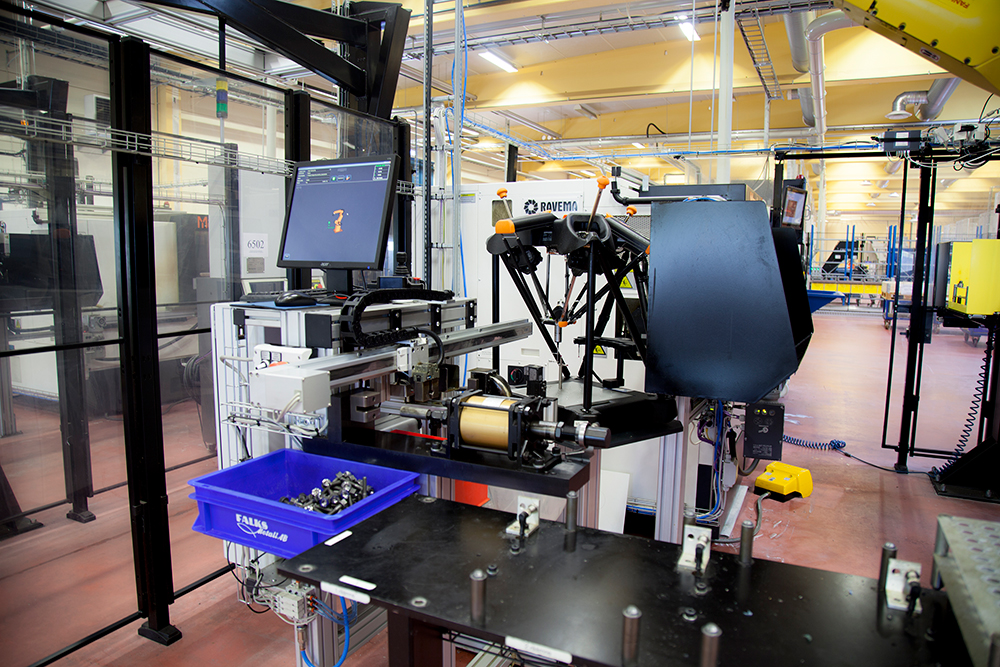

Våra uppdrag har helt olika krav på toleranser och kvalitetsmått. Men gemensamt är att utvecklingen går mot att kunna leverera så nära noll fel som möjligt. För att möta upp den utvecklingen har vi investerat, inte bara i avancerad mätutrustning utan i inspektionsmaskiner för 100% kontroll. Vi har kapacitet för att inspektera stora volymer från både vår egen och andras produktion (legosortering). Dessutom har delar av vår produktion försetts med mätutrustning för inspektion som är integrerat i produktionscellen. Vi analyserar också OEE, Overall Equipment Effectiveness och vårt mål är att ligga på nivån 80%.