Induktionshärdning

Induktionshärdning är en metod för att lokalt öka ythårdheten, utan att påverka kärnhårdheten hos ett material. Det gör att de delar av artikeln som inte härdningsbehandlas förblir mjuka. Ythårdheten och slitagemotståndet ökar utan att artikelns svarvade mått och toleranser påverkas.

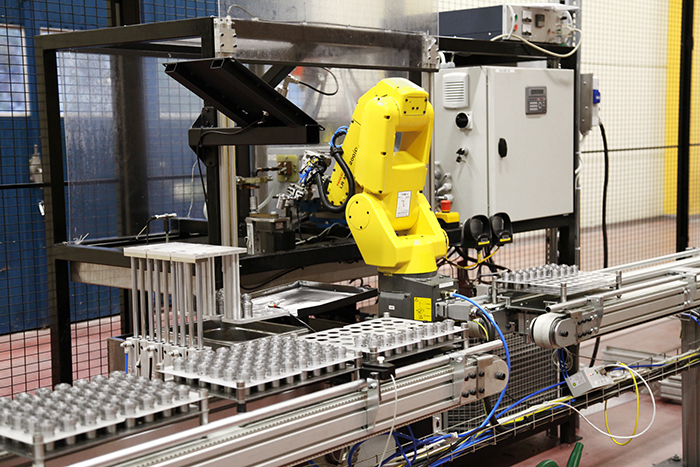

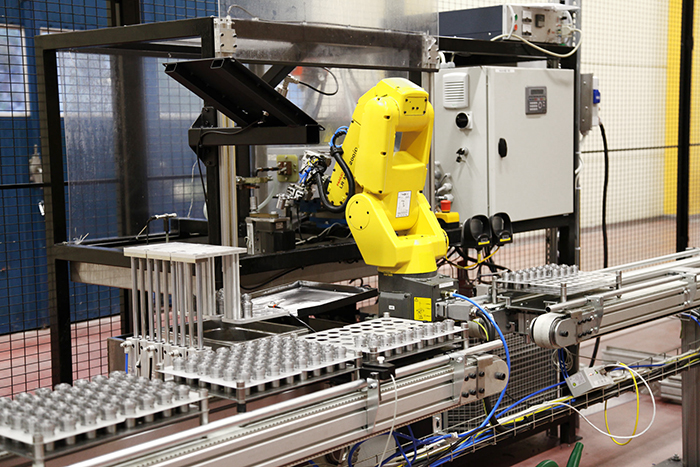

En del av processen

Vi har induktionshärdning integrerat i en del av vår produktionsanläggning för svarvning. Detta gör att vi väver ihop flera tillverkningsprocesser i en cell. Artiklarna testas efter härdning i vårt labb där vi kontrollerar och kvalitetssäkrar hårdheten. Sammantaget har detta skapat stora vinster i effektivitet och kvalitet åt våra uppdragsgivare. Mer än svarvning helt enkelt.

Fråga oss vad du vill

Vi svarar inom 24 h. Fråga oss om:

- Standardmaterial

- Speciallegeringar

- Svarvning

- Fräsning

- Noll fel - hur når vi det?

- Vårt bolag i Kina