MORE THAN TURNING

We strive for zero defects

In a plant of 7,500 square meters, we produce machined articles in most common materials. We have built up a world-class production where technology and competence development are followed in our quest for zero defects. All production is based on our vision of sustainability for both the environment and humans, and with a very high degree of automation, we achieve high demands on traceability and purity. We learn every day and we love to carry out development work together with our customers. Welcome to Falks Metall AB.

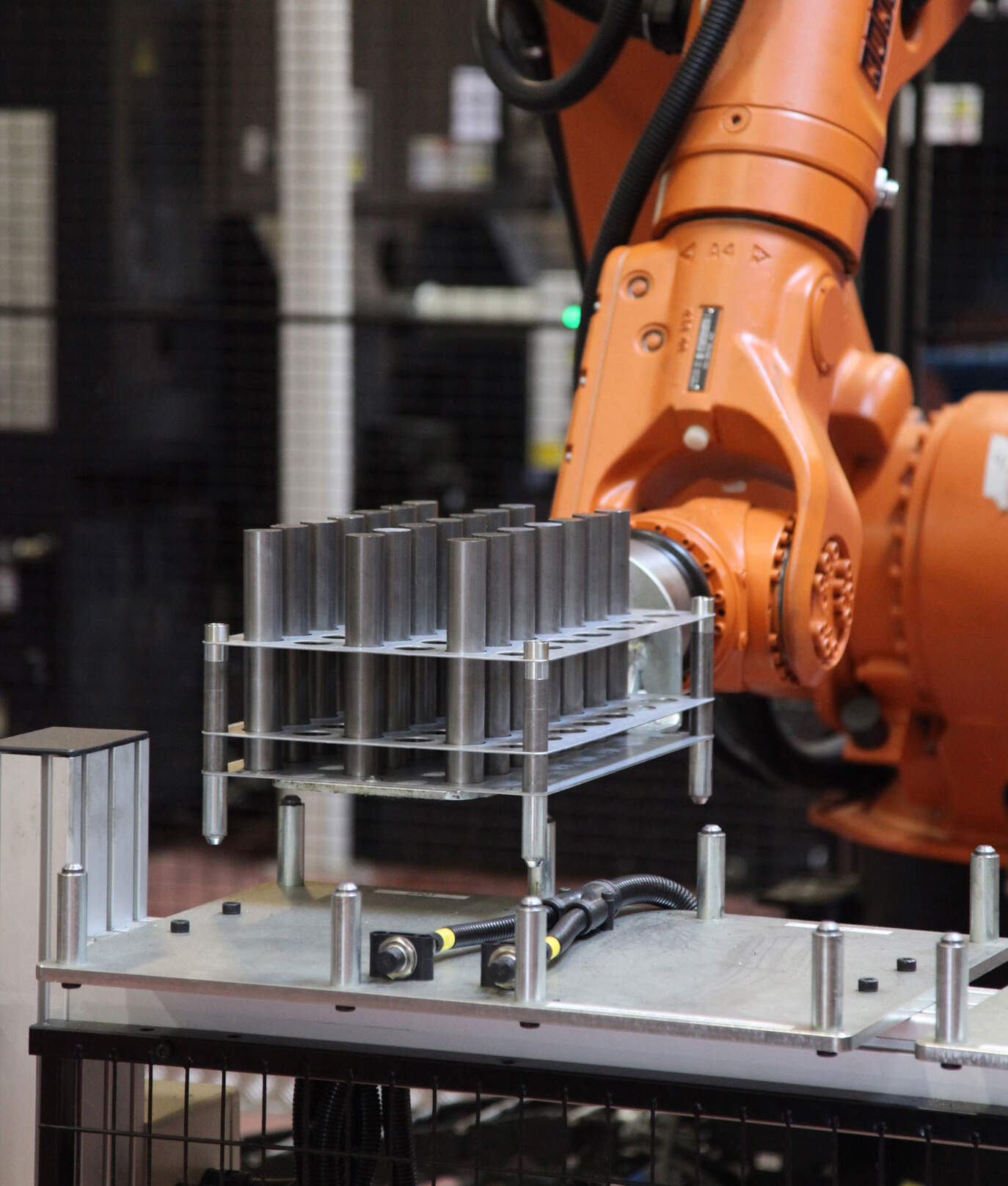

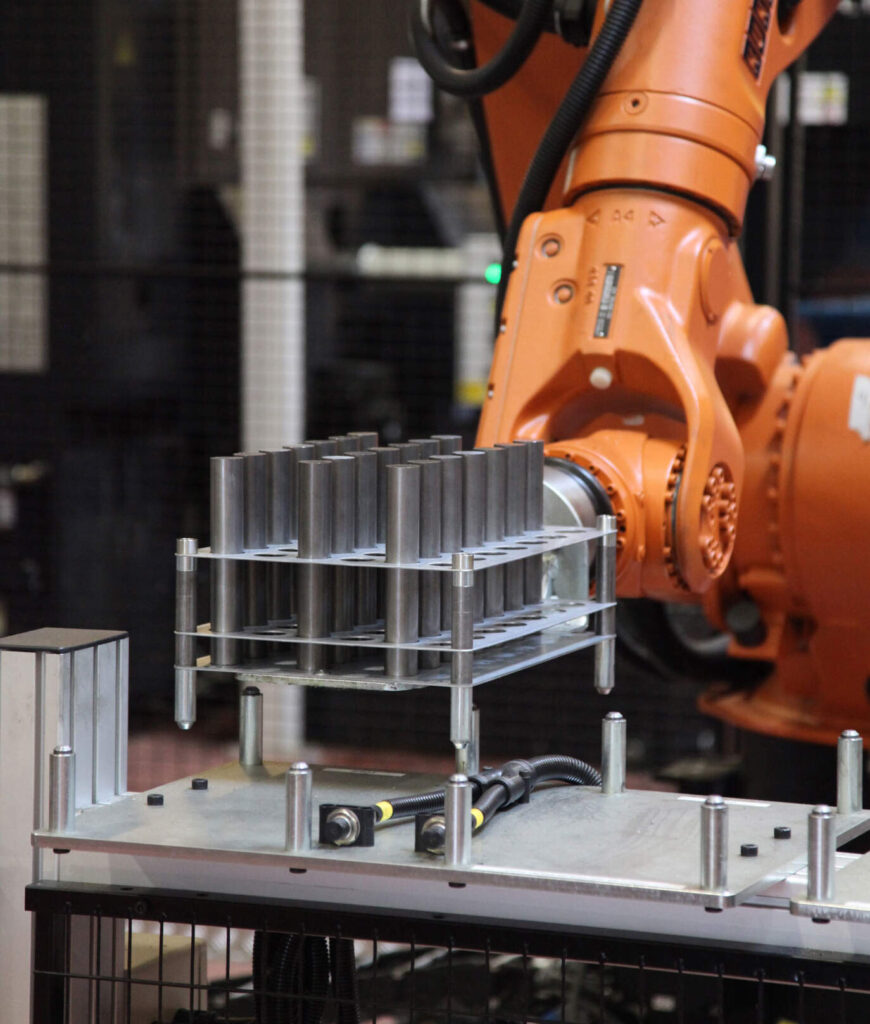

Near net shape

Near net shape is about starting the processing with a substance that is as close to the final shape of the article as possible. It minimizes material waste and contributes to efficiency both in time and costs. We have worked for many years to create a facility that is as flexible as possible based on the size and complexity of different items. We process putty, cast and forged blanks into finished details. Everything is based on a pallet system and on the Near Net Shape principle.

Near net shape

Near net shape is about starting the processing with a substance that is as close to the final shape of the article as possible. It minimizes material waste and contributes to efficiency both in time and costs. We have worked for many years to create a facility that is as flexible as possible based on the size and complexity of different items. We process putty, cast and forged blanks into finished details. Everything is based on a pallet system and on the Near Net Shape principle.

Materials - standard and special alloys

With more than 70 years of experience, we have processed most of the existing materials. We have extensive experience of stainless materials and continuously use, for example, 254SMO® and 1.4404 to manufacture turned and milled articles. The development in materials is incredibly exciting to follow and to adapt our production to all the desired properties of the finished articles is a matter of course. Our customers' needs start with the choice of material. Read more here

Quality work

Our production facility is highly automated and optimized for high OEE numbers and 100% traceability. We are certified according to ISO 9001. Download certificate here.

Environmental work

Minimizing all forms of waste and waste of resources is in our nature as we are Smålanders in heart and soul. We are certified according to ISO 14001.

Download certificate here.

Quality IATF

Investments in advanced measuring equipment and inspection machines guarantee the high quality. Falks are certified according to IATF 16949. Download certificates here.

Quality ISO 13485

For our customers in medical technology, documentation and purity are central and we can offer solutions that meet these high demands. We are actively working towards a certification according to ISO 13485.

Falkwork®

Our corporate culture is important to us and we want our workplace to be characterized by well-being and a desire to solve tasks. To develop at work and to develop the job together. We call this Falkwork®

We're Falks

We are an experienced team that is ready to listen and help you move forward. Here you will find information about us for a personal contact.

Our sourcing center in Shenzhen

Since 2002, we have a quality and logistics center in Shenzhen, China. This subsidiary acts as a sourcing center to find the best suppliers in each segment. Through the own quality department filled with measuring equipment such as coordinate measuring machine, shape and surface evenness meter, hardness laboratory, the goods are checked before they are sent on. You control quality and coordinate deliveries. The company also has its own production and assembly. Through a local presence, we can both have a close contact with our suppliers and at the same time handle deliveries to our customers in the Asian market. We have a number of customers where we handle warehousing and delivery for the European market in Gnosjö and corresponding handling for the Asian market in Shenzhen.

Our sourcing center in Shenzhen

Since 2002, we have a quality and logistics center in Shenzhen, China. This subsidiary acts as a sourcing center to find the best suppliers in each segment. Through the own quality department filled with measuring equipment such as coordinate measuring machine, shape and surface evenness meter, hardness laboratory, the goods are checked before they are sent on. You control quality and coordinate deliveries. The company also has its own production and assembly. Through a local presence, we can both have a close contact with our suppliers and at the same time handle deliveries to our customers in the Asian market. We have a number of customers where we handle warehousing and delivery for the European market in Gnosjö and corresponding handling for the Asian market in Shenzhen.